THE CLIENT:

Torque Technologies, based in Sarasota, Florida, is the exclusive distributor of Goizper brand clutches and brakes in North America. Goizper brand products are sold worldwide and have a reputation for high quality, precision engineering and flexible design.

THE CHALLENGE:

Automotive stamping operations were experiencing rapid growth, with the advent of Electric Vehicle production. To meet the need for stamping capacity, many firms were looking at repairs and retrofit of older equipment, given the high expense of new stamping presses.

Goizper’s clutches and brakes, widely known in Europe and Asia in the OEM market, had a much smaller following in North America. Competition from American and German firms, with an installed base of OEM clutches, brakes, and clutchbrakes on popular late-model presses, presented an obstacle to be overcome.

THE SOLUTION:

Torque Technologies, Inc., as the exclusive US distributor for Goizper power transmission products, hired Custom Direct to develop a comprehensive campaign, with white papers, case studies, worksheets, and detailed data – designed to showcase the tremendous cost (and time) benefits of considering a retrofit solution, using Goizper’s fully interchangeable product line. Operations, Finance, and Engineering staff at metal fabrication and stamping facilities were targeted with the messaging.

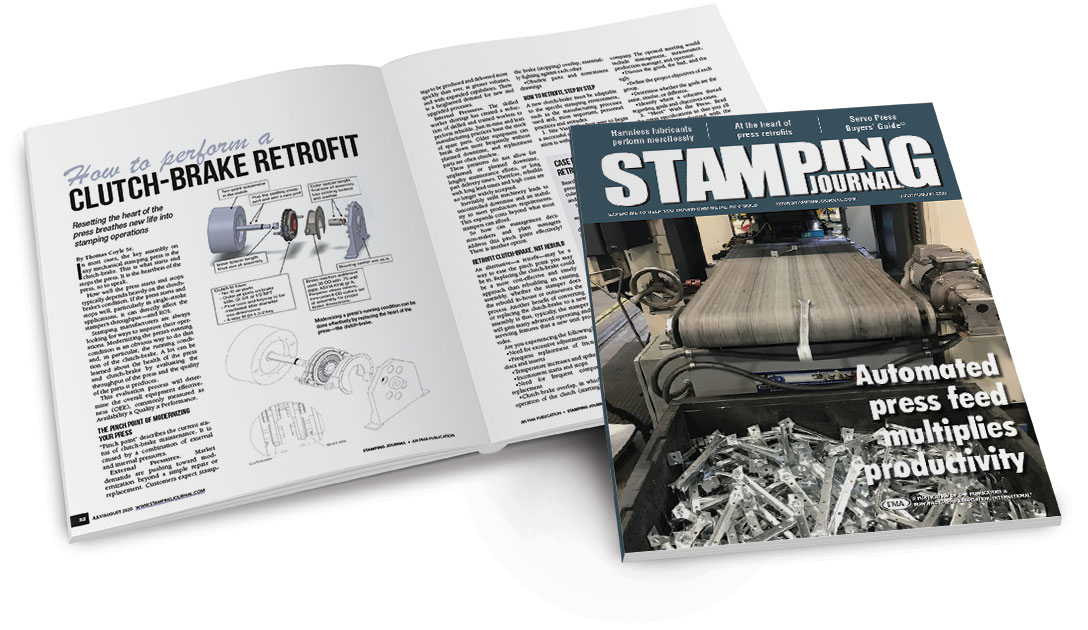

Building on successful email and LinkedIn campaigns, Custom Direct worked to increase overall brand awareness by pitching a bylined article in STAMPING Journal®, a premiere industry publication, reaching more than 23,000 professionals in the metal fabricating and forming industry each month.*

KEY RESULTS:

- 2.5 page, 1,200-word Feature Article with illustrations and a case study

- Invitation to host a webinar to Automotive Stamping financial professionals

- 200% increase in website and LinkedIn traffic

- Article featured on home page marquee at thefabricator.com†

“You wrote a great article our readers are sure to find informative. Geoff, you facilitated everything professionally and efficiently. It was my pleasure working with you all.”

Kate Bachman – STAMPING Journal® Editor ![]()